| Sign In | Join Free | My components-electronic.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My components-electronic.com |

|

Model Number : LYAPL1-20-I

Certification : CE, ISO, GMP

Place of Origin : China

MOQ : 1 unit

Price : USD 150,000-350,000 per unit

Payment Terms : D/A,D/P,T/T,Western Union,MoneyGram

Supply Ability : 1 unit per month

Delivery Time : 180 work days

Packaging Details : carton, wood carton, pallets

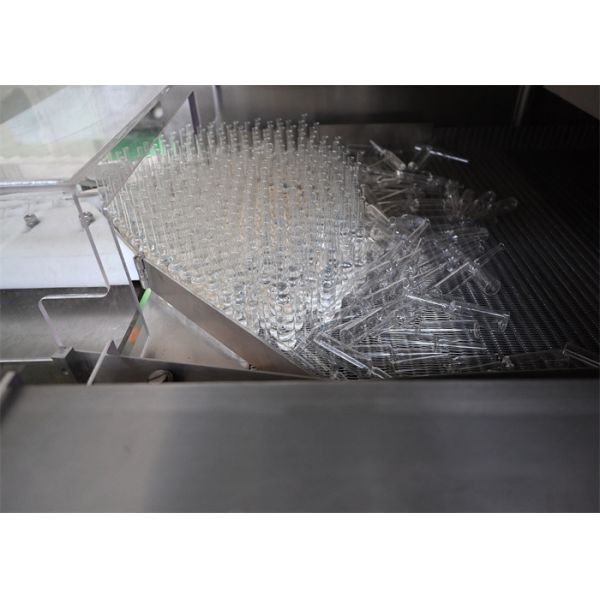

Machine Name : Ampoule Filling Line

Function : Ampoules Washing, Sterilization, Filling, Sealing

Scalability & Flexibility : 1-20ml glass ampoules

Filling Liquid Type : Vaccine and Biologics

Max Output Capacity : 34000 BPH

Ampoules Material : Glass

Breakage Rate : <0.5%

Nitrigon Filling : Yes

CIP/SIP : Yes

Oven Cooling Style : Air Cooling

Sterilization Capability : Integrated sterilization processes(ultrasonic cleaning, dry heat sterilization)

LAF System : Yes

After-sales Service & Technical Support : 1-2 years guarantee maintenance, free spare parts available, and troubleshooting assistance to minimize downtime

Energy Efficiency : water, energy aligned with sustainability goals

Aseptic Ampoule Filling Line for High Precision Vaccine and Biologics EU GMP Compliant, 99.9% Sterility Assurance

Revolutionize Your Sterile Ampoule Production with Smart Aseptic Filling

The Aseptic Ampoule Filling Line is engineered to meet Europe’s stringent pharmaceutical standards, combining cutting-edge isolator technology with AI-driven process control. Designed for critical applications like mRNA vaccines and monoclonal antibodies, this line ensures 99.9% sterility assurance through HEPA-filtered laminar airflow and real-time particulate monitoring.

Why European Clients Choose This Line:

✅ Zero Cross-Contamination – Closed-system RABS (Restricted Access Barrier System) with glove ports for operator safety.

✅ Adaptive Format Switching – Automatically adjusts between 1ml insulin ampoules and 20ml diagnostic reagents in ≤3 minutes.

✅ Green Manufacturing – Heat recovery from sterilization tunnels reduces energy waste by 18%.

✅ Blockchain Traceability – Embedded IoT sensors log every ampoule’s fill weight, seal integrity, and sterilization parameters for EU MDR compliance.

Aseptic Ampoule Filling Line Spec:

| technical parameters | ||||

| product model | LYQCL100+LYASMR 620/43+LYAGF8 | |||

| size range | 1-20ml national standard ampoules | |||

| Output(1-2ml) | 16000-22000pcs/h | |||

| Output(5-10ml) | 8000-12000pcs/h | |||

| Output(20ml) | 5000-7000pcs/h | |||

| Clarity | >99% | |||

| Breakage rate | ≤1%(whole line) | |||

| Filling Precision | ±0.5-2%(according to pharmacopoeia standard) | |||

| Water Consumption and Pressure | 0.2-0.4Mpa / 0.6-1.0m³/h | |||

| Cleaning CA Consumption and Pressure | 0.3-0.6Mpa / 35-80m³/h 0.3-1.0Mpa / 35-80m³/h | |||

| Sealed gas | Gas(liquefied gas)+oxygen, oxyhydrogen generation gas, natural gas | |||

| Oxygen consumption | 0.2-0.3Mpa,1.2-1.5m³/h | |||

| Gas consumption | 0.1-0.3Mpa,1.5-2.5m³/h | |||

| Exhaust volume | 3500-4100m³/h | |||

| Net weight | 7800(kg) | |||

| Total power | around 72kw 380V 50HZ | |||

| Outline size | around 9940x2260x2445mm | |||

Real-World Application Spotlight

A Swiss biotech firm reduced fill-loss by 37% using this line’s pulsed volumetric filling technology, crucial for €10,000+/liter gene therapies. The machine’s anti-vibration platform also minimized liquid splashing during high-speed filling of adjuvanted flu vaccines.

Technical Edge

|

|

Aseptic Ampoule Filling Line for High Precision Vaccine and Biologics EU GMP Compliant, 99.9% Sterility Assurance Images |